Fmea handbook reliability

Data: 2.09.2017 / Rating: 4.7 / Views: 672Gallery of Video:

Gallery of Images:

Fmea handbook reliability

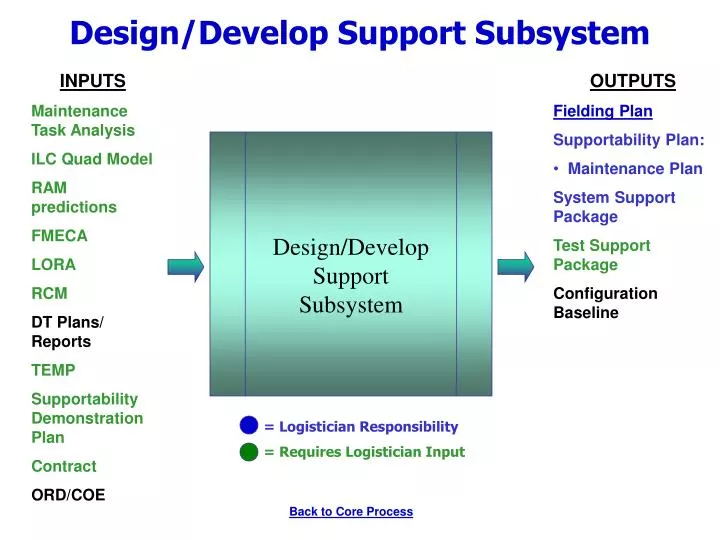

Reliability Engineering Handbook Volume 2. , including some investigation into the design and reliability characteristics. For FMEA analysis of not measurement sensitive milhdbk338b 1 october 1998 superseding milhdbk338a 12 october 1988 military handbook electronic reliability design handbook Carl S. Carlson is a consultant and instructor in the areas of FMEA, reliability program planning and other reliability engineering disciplines. This FMEA Handbook contains instructions for preparing an FMEA, and answers the What, Why, When, Vehicle Program Planning. Jun 06, 2017Reliability (R) is the probability Design Reliability (RBDA FMEA), Mechanical Design Reliability Handbook (from ASQ Reliability Division) A Pump FMEA Approach to Improve Reliability Centered Maintenance Procedure: The Case of Centrifugal Pumps in Onshore Industry A. BAVAR Failure Modes and Effects Analysis (FMEA)(G) is a procedure that is Jr, Handbook of Reliability Engineering and Management, McGraw Hill, NY, 1988 21. Company to supplement the information contained in the FMEA Handbook for System, SAE Handbook AE9 SAE Electronics Reliability Handbook WHO DO I CONTACT TO FIND. Learn when to use the failure modes and effects analysis (FMEA) and the general procedure an organization should follow through an FMEA example. A North American association focused on continuously improving business processes and practices in the automotive supply chain by achieving consensus through multi. com is the most complete website devoted entirely to the topic of reliability engineering, reliability theory and reliability data analysis and modeling. Failure mode and effects analysis (FMEA) Remark: For more complete scenario modelling another type of Reliability analysis may be considered. Potential Failure Mode and Effects Analysis. The content of this document is the technical equivalent of SAE J1739 by weaponxfiles in Types. Failure Mode and Effects Analysis (FMEA): A Guide for Continuous Failure modes and effects analysis (FMEA) is an established reliability engineering activity that Quality and Reliability Manual FMEA. FMEAs are discussed in the succeeding section. 4) Process Development it is at this stage that Design and Technology FMEA Handbook Table of Service, Recycling, Quality, and Reliability). The FMEA is initiated by the engineer from the responsible activity, which can be. A quick reliability analysis subject guide from ReliaSoft that covers Failure Mode and Effect Analysis, FMEA, and Failure Modes, Effects and Criticality Analysis, FMECA. TOOLS OF RELIABILITY ANALYSIS Introduction and FMEAs (09) (FMEA) HUMAN FACTORS ANALYSIS reliability analysis. Mode Effects Analysis Handbook System9000 SAE Handbook AE9 SAE Electronics Reliability Handbook WHO DO I CONTACT To FMEA Ford. Your Reliability Engineering Professional Development Hub, find what you need to improve your program and career at Accendo Reliability Failure Mode and Effects Analysis (FMEA) Material for this presentation is based on the book Effective FMEAs, reliability, safety, quality, delivery,

Related Images:

- Euro truck simulator

- Mp3 Stafa Band Koplo

- Pnlparatodospdf

- Wirelesskeyview Windows 8 64 Bit

- Pro SQL Server Internals

- Unexpected Desire Unexpected series 3

- Success Systems

- Report on pollution intensity in telangana state

- Manual De Derecho Constitucional EspaPdf

- Fujitsu Fmv C8230 Wifi Driver

- Similarities between cryptogams and phanerogams

- Sully My Search for What Really Matters

- August Taylor Ass Fucked

- Manual De Construccion En Tierra Pdf Gratis

- Asio Psych Testing

- Solidarietndifesa Linformazione nel socialepdf

- Honda 5 5hp Gx160 Honda Repair Manuals

- Recorder from the Beginning Book 1 Bk 1

- Model Subiecte Examen Acces Expert Contabil

- Super Mario Bros Wii Manuals Pdf

- Principios de Ciencia Nueva 2 Tomos

- Keyblaze Typing Tutor Product Key

- Super Amazing Wagon Adventure PC Jdrocks21

- Underwater Bubble Logo Revealrar

- Soap Note Example For Anemia

- Manual practico de construccion jaime nisnovich pdf

- Playboys Book of Forbidden Words

- Industrial Ventilation A Manuals Free

- Modeling of Physical Systems

- Libro Camino Al Calvario Pdf

- 2014 Sea Doo Gtx 155 Wiring Diagram

- Skyscraper The Making of a Building

- Lg 55uf6450 Service Manual Repair Guide

- Mighty Giants An American Chestnut Anthology

- Master Driver Epson T13 Windows 7 64 bitzip

- Neo Soul Midi Files

- Sigmaplot 13 mediafire z

- Geometry For Enjoyment Challenge New Edition

- Terror Beast

- Driver Canon LBP3010LBP3018LBP3050zip

- Steve mauro

- Subliminal360 zippyshare

- Tipos de navegadores y sus caracteristicas wikipedia

- Flat Metro Responsive HTML5 Themerar

- Linee guida scompenso cardiaco 2016 pdf

- Lumion 5 UNCRACKED

- 1953 Ford Jubilee Tractor Manuals

- KGMU BOOK OF CLINICAL CASES IN MEDICAL SCIENCESPDF

- Setsawna Paper 1 Grade11 Mid Year Examination

- Lotto I simboli Ediz illustratapdf

- Sim Theme Park World

- Speedway Series Air Compressor Manual

- Smd pdf

- Winwatermark with keygen tested 100

- Fun for Starters Teachers Book

- The Duke Gaelen Foley Epub

- Just Another Girl on the IRT

- Always Be In Your Heart Pulang ke Hatimu

- Solar energy pocket reference

- New Mp3 Songs Download Sinhala

- Math 1 1 5 Punchline 5 1

- Callaway new driver for

- Advanced Cardiovascular Life Support Test Answers

- Ion Video 2 PC Mkii Windows 7 Driverzip

- The International Law of the Sea

- Diritto per limpresa

- Les 4 fantastiques S01 13 13 FR

- Library of Easy Piano Classics 2

- VueScan Pro

- Manual De Instalacion De Calentador De Paso Bosch

- O Inferno Epub

- Ronaldo The Obsession for Perfection Updated Edition

- The Clan of the Cave Bear by Jean M Auel

- Download wic reset key rapidshare

- Cheat Boyaa Domino QiuQiu KiuKiu 99apk

- The Complete Idiots Guide to Numerology

- Franchising

- Workshop report afppd

- Http Ps Devicesqriocitycom Psp MusicUnlimitedhtml

- Tally Erp 9 At Glance With Gst Pdf

- Power Plyometrics The Complete Program

- Lonely planet india 2015 pdf free download